Cupro Nickel 70/30 Wire, 70/30 Cu-Ni Coil Wire,Copper Nickel 70/30 Wire, 70/30 Cupro Nickel Wire, ASTM B206 Cupro Nickel Coiled Wire Suppliers and Exporters in Mumbai, India.

Cu-Ni WERKSTOFF NR. 2.0882 Wire, Cupro Nickel UNS C71500 Bright Wire, Exporters of Copper Nickel 70/30 Zinc Wire, ASTM SB206 70/30 Copper Nickel Wire Manufacturer in India.

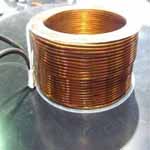

PRATAP STEEL INDUSTRIES india is a known manufacturer and exporter of Copper Nickel 70 / 30 Wire which is offered in best prices to our clients. Cupro Nickel 70 / 30 Wire is often used in Ferrules, Welding Backing Rings, Flexible Metal Hose, Weld Wire, Boiler Parts, Condensers, Propeller Sleeves, and Heat Exchanger Components. We also provide a link between research and user industries for Cupro Nickel 70 / 30 Wire and maintain close contact with other copper development associations throughout the world. Cupro Nickel 70 / 30 Coil Wire also has excellent resistance to attack by fresh water, boiler feedwater, steam and it’s withstands the attack of phosphoric, sulfuric, and mild organic acids. Cupro Nickel 70 / 30 Wire is often referred to as Copper Nickel 70/30 because it is made up of 30 % nickel in its composition. Cupro Nickel 70 / 30 coiled Wire is widely used in marine service, tidewater power plants, desalinization plants, oil refineries, and in the chemical process industry. Cu-Ni 70 / 30 Wire fined its greatest application in areas of high temperatures and pressures combined with high velocity and destructive turbulence. This bond forms long, hard chips in Cu-Ni 70 / 30 Wire that cause irreparable surface damage when machined down. Cu-Ni 70 / 30 Coil Wire also has good fabricability and high inherent resistance to biofouling.

Cupro Nickel 70/30 Wire Specifications

Â

Types of Cupro Nickel 70/30 Wire

|

Cupro Nickel 70/30 Wire | Cupro Nickel 70/30 Wire 70/30 Cu-Ni Wire Copper Nickel 70/30 Wire Cupro Nickel UNS C71500 Wire Cupro Nickel WERKSTOFF NR. 2.0882Â Wire ASTM B206 70/30 Cupro Nickel Wire |

|

Cupro Nickel 70/30 Coil Wire | Cupro Nickel 70/30 Coil Wire 70/30 Cu-Ni Coil Wire Cupro Nickel Alloy 70/30 Steel Coil Wire Copper Nickel UNS C71500Â Coil Wire Cupro Nickel WERKSTOFF NR. 2.0882Â Coil Wire ASME SB206 70/30 Nickel Coil Wire |

Â

70/30 Cupro Nickel Wire Chemical Composition

| Grade | Cu | Mn | Pb | Ni | Fe | Zn |

| Cupro Nickel 70/30 | 65 min | 1.0 max | 0.05 max | 29-33 max | 0.4-1.0 max | 1 max |

Cupro Nickel 70/30 Wire Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 0.323 lb/in3 at 68 F | 2260 F | 50000 psi | 20000 psi | 30 % |

Equivalent Grades for 70/30 Cupro Nickel Wire

| STANDARD | WERKSTOFF NR. | UNS |

| Cupro Nickel 70/30 | 2.0882 | C71500 |

Cupro Nickel 70/30 Wire Price List

- 70/30 Copper Nickel Wire

US $900-7771 / Metric Ton (FOB Price) - Cupro Nickel 70/30 Wire

US $900-7771 / Metric Ton (FOB Price) - Copper Nickel 70/30 Zinc Wire

US $900-7771 / Metric Ton (FOB Price) - ASTM B111 70/30 Copper Nickel Wire

US $900-7771 / Metric Ton (FOB Price) - ASME SB206 70/30 Cupro Nickel Wire

US $900-7771 / Metric Ton (FOB Price)

Cupro Nickel 70/30 Wire Application Industries

- Off-Shore Oil Drilling Companies

- Power Generation

- Petrochemicals

- Gas Processing

- Specialty Chemicals

- Pharmaceuticals

- Pharmaceutical Equipment

- Chemical Equipment

- Sea Water Equipment

- Heat Exchangers

- Condensers

- Pulp and Paper Industry

70/30 Cupro Nickel Wire Test Certificates

We at GIC provide Manufacturer TC (Test Certificate) in accordance to EN 10204/3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report. We also provide Standard certificates like EN 10204 3.1 and additional requirement like. NACE MR 01075. FERRIT CONTENT as per norms if requested by clients.

• EN 10204/3.1B,

• Raw Materials Certificate

• 100% Radiography Test Report

• Third Party Inspection Report, etc

ASTM, ASME Cupro Nickel 70/30 Wire Value Added Services

Material Testing:

We at PRATAP STEEL INDUSTRIES ensure that all our materials go

through strict quality tests before dispatching them to our clients.

• Mechanical Testing Such as Tensile of Area

• Hardness Test

• Chemical Analysis – Spectro Analysis

• Positive Material Identification – PMI Testing

• Flattening Test

• Micro and MacroTest

• Pitting Resistance Test

• Flaring Test

• Intergranular Corrosion (IGC) Test

Documentation

• Commercial Invoice which includes HS Code

• Packing List including net weight and gross weight, number of boxes, Marks and Numbers

• Certificate of Origin legalized/attested by Chamber of Commerce or Embassy

• Fumigation Certificates

• Raw Material Test Reports

• Material Traceability Records

• Quality Assurance Plan (QAP)

• Heat Treatment Charts

• Test Certificates certifying NACE MR0103, NACE MR0175

• Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2

• Guarantee Letter

• NABL approved Laboratory Test Reports

• Welding Procedure Specification/Procedure Qualification Record, WPS/PQR

• Form A for the purposes of the Generalized System of Preferences (GSP)

Cupro Nickel 70/30 Wire Packaging

Â

Cupro

Nickel 70/30 Wire are individually wrapped by hand to ensure that the

high quality of the material is maintained and no damage in the last

stages of production. We recommend Plywood cases or pallet packaging to

ensure safe packaging and prompt delivery of the ordered consignment.

70/30 Cupro Nickel Wire come with imprints relevant to the job

information (eg, heat number, size, material and part number). This

information is also printed along all delivered Wire. Cupro Nickel 70/30

ASTM B111 Wire packing will be according to international standard in

bundles strapped by strips then into containers to avoid any damage.

Cupro

Nickel 70/30 Wire are individually wrapped by hand to ensure that the

high quality of the material is maintained and no damage in the last

stages of production. We recommend Plywood cases or pallet packaging to

ensure safe packaging and prompt delivery of the ordered consignment.

70/30 Cupro Nickel Wire come with imprints relevant to the job

information (eg, heat number, size, material and part number). This

information is also printed along all delivered Wire. Cupro Nickel 70/30

ASTM B111 Wire packing will be according to international standard in

bundles strapped by strips then into containers to avoid any damage.